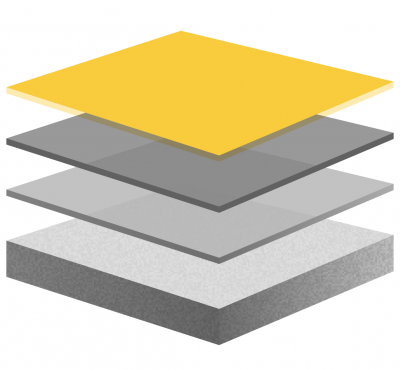

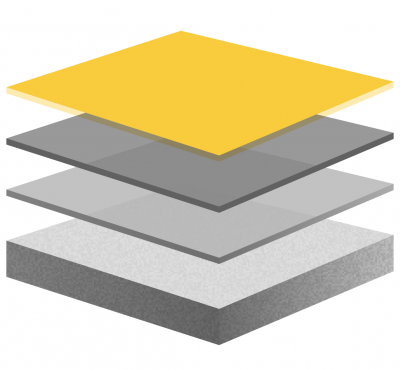

Thick-layer machine-trowelled system

System for environments with a risk of temperature changes.

Applied in two or three steps.

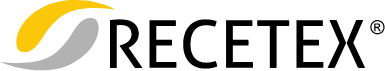

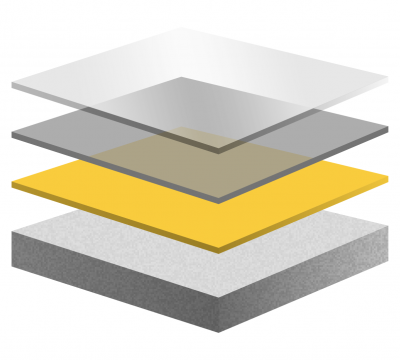

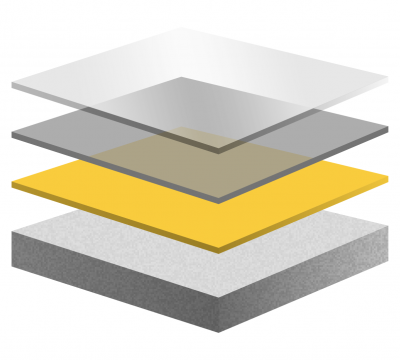

Two/three steps application:

Base layer | Polyurethane-cement primer | Body coat | Final layer

Polyurethane-cement primer

First layer consists of a three-component polyurethane-cement primer, Recepuc Primer TX, applied using a nylon roller or metal trowel at a specified consumption rate of 0.5–0.7 kg/m². The surface is then broadcast with coarse quartz sand (grain size 1.0–2.5 mm) at a rate of 2 kg/m². Any excess sand is subsequently removed.

Base layer | Polyurethane-cement primer | Body coat | Final layer

Body coat

The final structural layer consists of Recepuc Base, a three-component polyurethane-cement concrete (polymer concrete). The material includes all necessary components (including sand); only a pigment is added before application to achieve the desired final floor color. Thanks to its granular consistency, the mix is optimized for both machine and manual troweling.

The combination of inorganic binder (cement) and resin (polyurethane) makes it ideal for environments subject to thermal shock (e.g., food processing facilities). This layer seals the surface without needing a topcoat.

Base layer | Polyurethane-cement primer | Body coat | Final layer

Base layer | Polyurethane-cement primer | Body coat | Final layer

Final layer

Final layer consists of a water-based polyurethane coating, Recepur Coating WB TX, applied at a specified consumption of 0.45 kg/m². The coating is applied in two layers — the first serves to seal the pores of the polymer concrete, and the second acts as the final topcoat. The coating is UV-resistant and resistant to thermal shock.

Base layer | Polyurethane-cement primer | Body coat | Final layer

Looking for a trusted partner to install your flooring system?

We’ll take care of everything through our proven external partner, ensuring a smooth and hassle-free process from start to finish.

Interested in any of our products? Contact us.

Would you like to test the material before making your purchase decision? We understand, which is why we offer you the opportunity to try the material completely FREE of charge.

Simply fill out the form below, and we will send the selected material sample to the address of your choice right away.