Antistatic Floor

ESD TX

Thin-layer system with a textured surface, without a graphite intermediate layer, suitable for environments where electrostatic discharge needs to be controlled (e.g., electronics manufacturing, laboratories, medical offices, logistics warehouses, etc.). It is a cost-effective solution for renovating old antistatic floors.

Thickness up to 0.4 mm

Surface resistance Rg < 1 GΩ

One grounding point per 50 m²

Roller application

Application of the ESD TX flooring in two steps:

Substrate preparation

The first essential step of the application is selecting a suitable primer for the given type of surface (non-cohesive/porous/greasy/new, etc.). The primer material directly influences the final appearance and functionality of the finished floor. We are happy to assist you in choosing the right primer to achieve the ideal result.

If the substrate needs to be levelled, the primer can be combined with sand and used as the body of the screed—a levelling mortar/scratch coat.

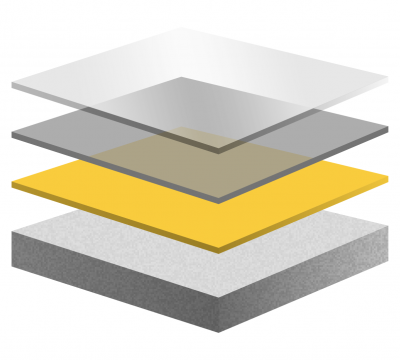

Surface | Penetration | Screed body (optional) | Final layer

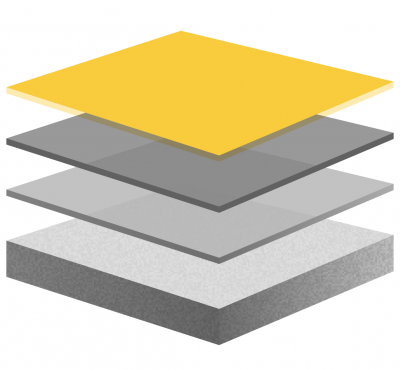

Surface | Penetration| Screed body (optional) | Final layer

Final layer

Before applying the final layer, conductive strips are adhered to the prepared and levelled substrate at a frequency of 1 grounding point per 50 m². The length of each conductive strip should be 50 cm.

Next, the final layer Recepox Coating SL AS W is applied using a trowel and a spiked roller at a consumption rate od 0.2-0.3 kg/m². The resulting system meets all requirements for an ESD environment.